Choosing the right stampings supplier plays a key role in achieving success. I have seen how a reliable supplier ensures high-quality production while keeping costs under control. They also help meet deadlines without compromising standards. A dependable stampings supplier can transform your project by delivering consistent results that align with your goals.

Key Takeaways

- Check if the supplier has experience and a good history. This shows they can handle your needs and do good work.

- Find suppliers who know the rules and have proper certificates. This proves they make quality products and follow the rules.

- Pick suppliers who talk clearly and are honest. This helps you trust them and prevents problems later.

Evaluating the Expertise of a Stampings Supplier

Proven Track Record in the Industry

When I evaluate a stampings supplier, I always start by looking at their history in the industry. A supplier with years of experience often has a deeper understanding of the challenges and solutions in metal stamping. I check for case studies or examples of past projects. These show me how they’ve handled similar requirements. A proven track record also means they’ve built trust with other clients. This reassures me that they can deliver consistent results.

Familiarity with Industry-Specific Standards

Every industry has unique standards. I’ve learned that a good stampings supplier knows these standards inside and out. For example, automotive or aerospace industries require precision and strict compliance. I ask if the supplier has worked with companies in my field. This helps me understand if they can meet my specific needs. Familiarity with standards like ISO or TS16949 ensures that the supplier can maintain quality and reliability.

Transparency in Communication and Processes

Clear communication is essential. I prefer suppliers who explain their processes openly. This includes how they handle designs, production, and quality checks. Transparency builds trust and helps me avoid surprises later. I also look for suppliers who provide regular updates. This keeps me informed about progress and any potential delays. A transparent supplier makes collaboration much smoother.

Assessing Production Capabilities and Capacity

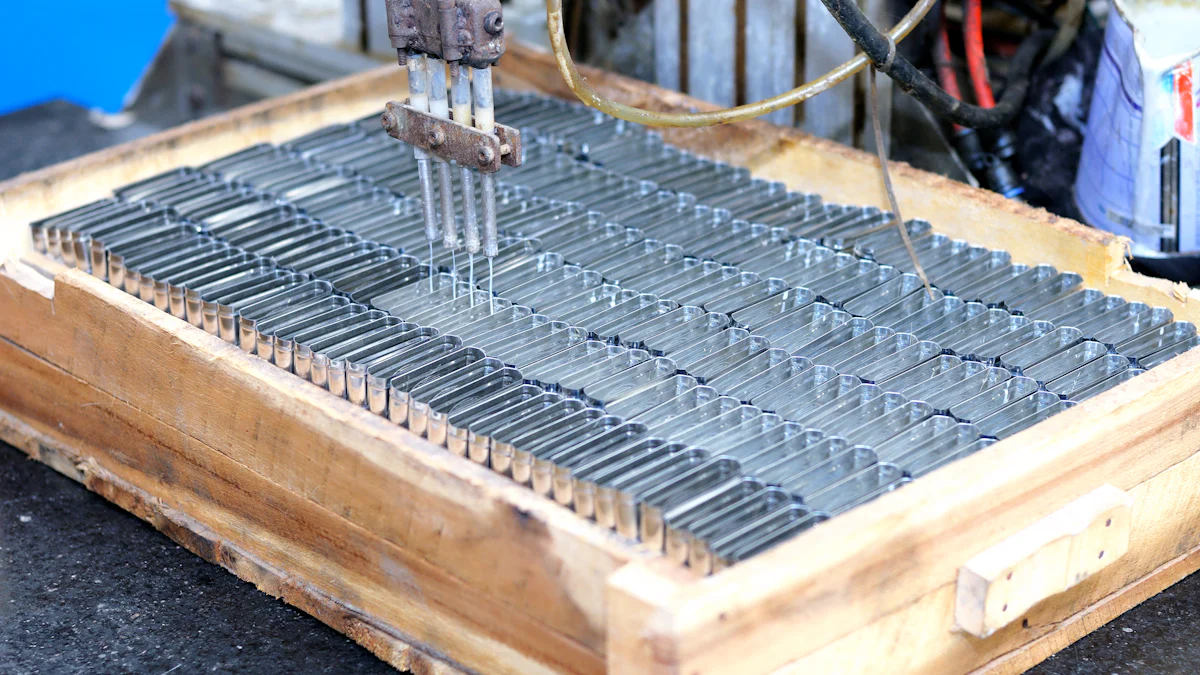

Advanced Equipment and Technology

I always check the equipment a stampings supplier uses. Advanced machinery ensures precision and efficiency. Modern tools can handle complex designs and maintain consistency. I’ve noticed that suppliers with cutting-edge technology often deliver better results. For example, CNC machines and automated stamping presses improve accuracy. These tools also reduce errors, which saves time and money. I also ask about their maintenance practices. Well-maintained equipment means fewer delays and higher reliability.

Material and Design Expertise

A good supplier understands materials and design. I look for those who can work with a variety of metals, like stainless steel or aluminum. This flexibility helps me choose the best material for my project. I also value suppliers who offer design support. Their expertise can improve my designs for better performance and cost savings. For instance, they might suggest changes to reduce waste or enhance durability. This collaboration makes the process smoother and more efficient.

Scalability for Complex or High-Volume Projects

Scalability is crucial for large or intricate projects. I evaluate if the supplier can handle high-volume production without compromising quality. I also check if they can adapt to complex requirements. A reliable supplier should manage both small prototypes and large-scale orders. This flexibility ensures they can grow with my needs. I’ve found that scalable suppliers are better partners for long-term projects.

Ensuring Quality Assurance and Certifications

Importance of ISO and Other Recognized Certifications

When I evaluate a stampings supplier, I always check for certifications like ISO. These certifications prove that the supplier follows strict quality standards. For example, ISO 9001 ensures that the supplier has a strong quality management system. This gives me confidence that their processes are reliable and consistent. I also look for industry-specific certifications, such as TS16949 for automotive parts. These certifications show that the supplier understands the unique needs of my industry. A certified supplier reduces risks and ensures better results for my projects.

Robust Quality Control Processes

Quality control is essential for any successful project. I always ask suppliers about their quality control methods. A good supplier uses tools like inspections, testing, and monitoring at every stage of production. For instance, they might use advanced measuring equipment to check dimensions or test materials for strength. These steps help catch problems early, saving time and money. I also value suppliers who document their quality checks. This transparency shows me that they take quality seriously and are committed to delivering the best results.

Compliance with Industry Regulations

Regulations play a big role in metal stamping. I make sure the supplier complies with all relevant laws and standards. This includes safety, environmental, and industry-specific rules. For example, some industries require parts to meet strict environmental guidelines. A compliant supplier helps me avoid legal issues and ensures my products meet customer expectations. I always ask for proof of compliance, such as test reports or certifications. This step gives me peace of mind and builds trust in the supplier.

Balancing Cost-Effectiveness and Customization

Competitive Pricing Without Compromising Quality

When I evaluate a stampings supplier, I always look for competitive pricing. However, I never let cost overshadow quality. A good supplier strikes the right balance by offering fair prices while maintaining high standards. I often ask for detailed quotes to understand how costs are distributed. This helps me identify areas where I can save without sacrificing performance. For example, some suppliers use advanced production methods that reduce waste, which lowers costs. By choosing a supplier who values efficiency, I ensure my project stays within budget while meeting my expectations.

Custom Design and Prototyping Services

Customization plays a big role in metal stamping. I prefer suppliers who offer custom design and prototyping services. These services allow me to test and refine my designs before full production. For instance, a prototype helps me spot potential issues early, saving time and money later. I also value suppliers who collaborate with me during the design phase. Their expertise often leads to improvements that enhance functionality or reduce material usage. This partnership ensures my final product aligns perfectly with my requirements.

Long-Term Savings Through Efficient Production

Efficiency is key to long-term savings. I always assess how a supplier manages their production processes. A well-organized supplier minimizes delays and reduces material waste. For example, some suppliers use advanced machinery to streamline operations. This not only speeds up production but also ensures consistent quality. Over time, these efficiencies translate into significant cost savings. By partnering with a supplier who prioritizes efficiency, I can achieve better results while keeping expenses under control.

Additional Services and Value-Added Offerings

Design and Engineering Support

I always value a stampings supplier that offers design and engineering support. Their expertise helps me refine my ideas and turn them into practical solutions. For example, they might suggest adjustments to improve the strength or reduce the weight of a part. This guidance ensures my designs are both functional and cost-effective. I also appreciate when suppliers use advanced tools like CAD software. These tools allow me to visualize the final product and make changes before production begins. This collaboration saves time and avoids costly mistakes later.

Inventory Management and Just-in-Time Delivery

Managing inventory can be challenging, especially for large projects. I prefer suppliers who offer inventory management services. They help me keep track of parts and ensure I always have what I need. Just-in-time delivery is another feature I look for. It allows me to receive components exactly when I need them, reducing storage costs and minimizing waste. A supplier with strong logistics capabilities ensures smooth operations and keeps my projects on schedule.

Post-Production Services, Including Finishing and Assembly

Post-production services add significant value to any project. I often need finishing options like polishing, coating, or painting to enhance the appearance and durability of parts. Some suppliers also offer assembly services, which save me time and effort. By handling these tasks, they simplify my supply chain and ensure consistent quality. A supplier with comprehensive post-production capabilities becomes a one-stop solution for my needs.

Importance of Customer Support and Communication

Responsiveness and Accessibility

I always prioritize a stampings supplier that responds quickly to my inquiries. Timely responses show me that they value my time and are committed to addressing my concerns. Whether I have a question about production timelines or need clarification on a design, I expect the supplier to be accessible. A reliable supplier provides multiple communication channels, such as email, phone, or even live chat. This accessibility ensures I can reach them whenever I need assistance. In my experience, suppliers who respond promptly help me avoid delays and keep my projects on track.

Clear and Consistent Communication

Clear communication is essential for a successful partnership. I look for suppliers who explain their processes in simple terms. This includes updates on production progress, potential challenges, and delivery schedules. Consistency in communication builds trust and reduces misunderstandings. For example, I appreciate when a supplier provides regular status reports. These updates help me stay informed and make better decisions. A supplier who communicates clearly ensures that we are always aligned on project goals.

Building a Collaborative Partnership

A strong partnership goes beyond transactions. I value suppliers who take the time to understand my needs and offer tailored solutions. Collaboration allows us to work together to overcome challenges and improve outcomes. For instance, a supplier might suggest design adjustments to enhance efficiency or reduce costs. This proactive approach shows me that they are invested in my success. By building a collaborative relationship, I gain a trusted partner who supports my long-term goals.

Choosing the right stampings supplier can make or break a project. I’ve learned that expertise, production capabilities, and quality assurance are non-negotiable. Cost-effectiveness and additional services add even more value. I always recommend thorough research and evaluation. This approach ensures a reliable partnership and high-quality results every time.

FAQ

What materials can a metal stamping supplier work with?

Most suppliers handle materials like stainless steel, aluminum, brass, and copper. I always confirm their expertise with the specific material my project requires.

How do I ensure my supplier meets quality standards?

I check for certifications like ISO 9001 or TS16949. These certifications guarantee the supplier follows strict quality management processes and delivers reliable results.

Can a supplier handle both small and large production runs?

Yes, many suppliers offer scalability. I always ask about their capacity to manage prototypes and high-volume orders to ensure they meet my project needs.

Send your message to us:

Post time: Feb-06-2025